The Precision Craft of Diecasting: Revolutionizing Manufacturing

Diecasting is an advanced manufacturing process that plays a vital role in

creating sophisticated metal products with excellent precision and

reproducibility. This technique involves injecting molten metal into a mold

cavity using high pressure permitting the creation of precise shapes and

intricate designs that are difficult to create using other techniques.

Diecasting is widely utilized in diverse industries like electronics, aerospace,

automotive, and consumer goods, because of its effectiveness and capability to

create high-quality parts. This article explains the intricacies involved with

diecasting by detailing its process, benefits in use, and the potential

applications.

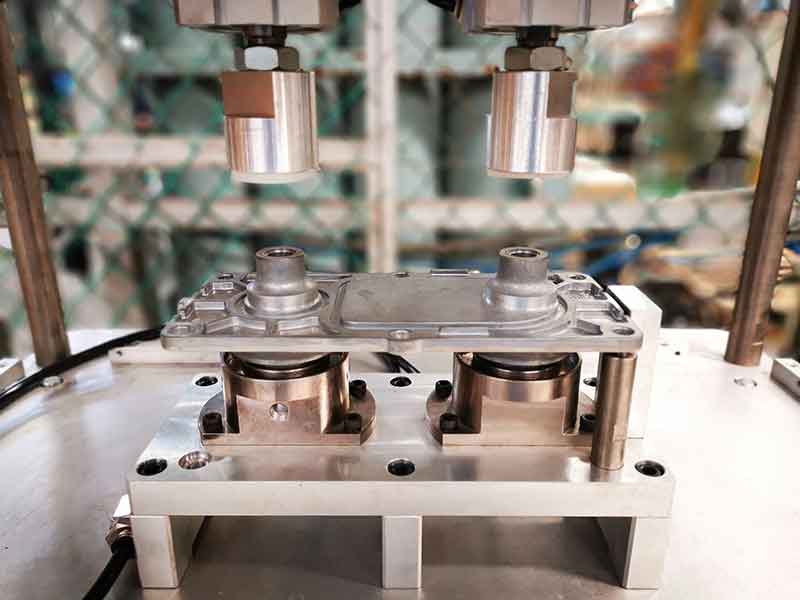

Diecasting begins with the design of the mold, sometimes

referred to as a"die," and is usually made of toughened steel. The mold is

constructed for the extreme pressures and temperatures involved during the

process. After the die has been made the molten metal, which is typically made

up of aluminum, zinc, magnesium, or copper, is heated up to an liquid state, and

introduced into the mold under pressure that is high. The pressure is kept up

until the material has solidified, so that the molten metal fills every part of

the mold with fine detail and the thin walls. After the metal has cooled and

formed, the mold is opened, and the finished component is removed. This

technique allows for high quality and precision with the manufacture of metal

parts.

One of the biggest advantages of diecasting is its effectiveness

in large-scale production. Once the dies are created it is possible to have the

process repeated numerous times with minimal variation between parts. The

repeatability is crucial to industries that require huge quantity of consistent

components. Additionally, diecasting is renowned for its material efficiency.

Diecasting produces less waste than other metal forming techniques because any

metal that is not used can be recycled and reused. This reduces not just the

cost of material but also promotes environmentally sustainable manufacturing

practices. Diecasting's speed and precision diecasting make it an ideal method

for making large amounts of parts quickly and consistently which allows

manufacturers to keep to strict production deadlines and the demands of

markets.

Diecasting can also produce products with exceptional mechanical

properties. The rapid cooling of the molten metal during the process of casting

results in an extremely fine-grain design, which increases the strength and

durability of the finished product. These components are well-suited for

projects that require high performance and reliability. For example, in the

automotive industry Diecast components are utilized in engines, transmissions,

and structural elements, where the strength-to-weight ratio is crucial to ensure

safety and efficiency of vehicles. Similar to the aerospace field diecast

components aid in the development of lightweight yet sturdy structures that are

essential to optimizing the efficiency of fuel and performance. To receive

further details kindly look at Senadiecasting

Diecasting's capabilities go beyond its mechanical

benefits to its flexibility in a variety of application. In the field of

electronics, diecasting can be utilized to make enclosures, heat sinks and

connectors to ensure that the devices are secure and perform perfectly. This

process is used in producing everyday consumer goods, from the kitchen appliance

to power tools, where precision and durability are paramount. Diecasting is a

process that can produce detailed and intricate parts makes diecasting an

attractive option to engineers and designers seeking to create new ideas and

increase product capabilities. In allowing a variety of different metals and the

integration of intricate features, diecasting supports the development of

advanced products across multiple industries.

Diecasting is an incredibly

productive and flexible manufacturing method which is essential to the

production of complex metal parts with high precision and consistency. The

ability of diecasting to produce parts that have intricate detail with tight

tolerances and polished surfaces makes it an indispensable tool for all sectors,

from automotive to aerospace to consumer electronics as well as beyond.

Different material types further increases the flexibility of diecasting. It

allows companies to select the best alloy to meet their needs. Technology

advances, and the need for top-quality and efficient components grows and

increase, diecasting will continue to be crucial for manufacturing which will

drive innovation and superiority in the field of production.

Comments

Post a Comment